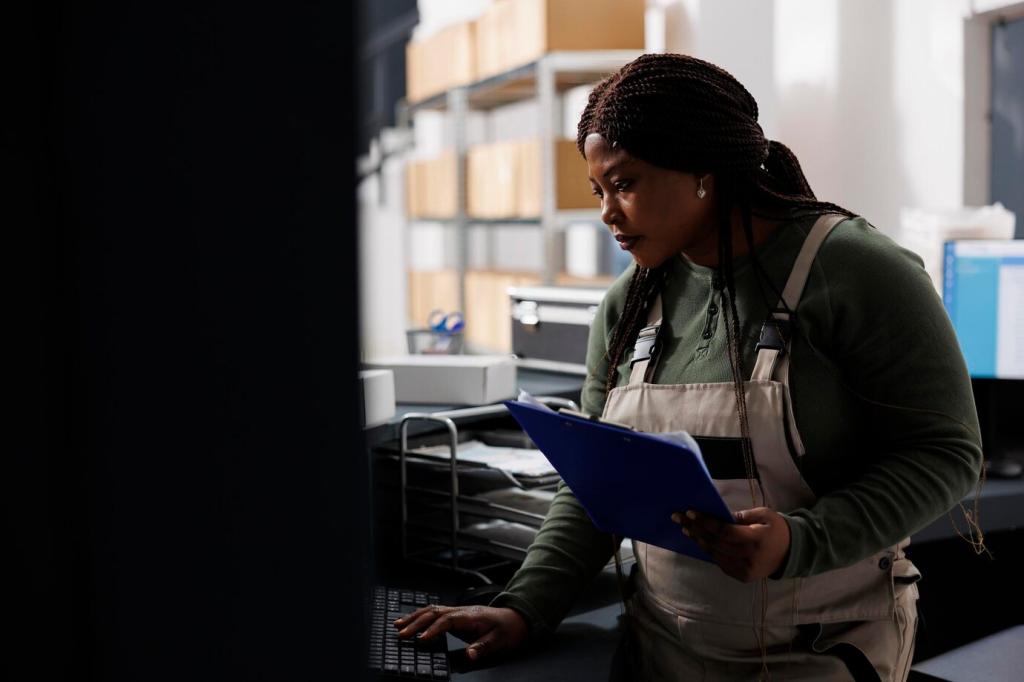

Data Analytics for Optimizing Warehousing: Turning Aisles into Advantages

Today’s chosen theme: Data Analytics for Optimizing Warehousing. Dive into practical insights, real-floor stories, and measurable tactics to transform receiving, picking, packing, and shipping into a data-driven symphony. Subscribe, comment, and join the conversation to share your warehouse’s biggest data win—or the challenge you want solved next.

Why Data Analytics Transforms Warehouses

01

From gut feeling to measurable outcomes

Warehousing thrives when tribal knowledge meets hard numbers. Analytics clarifies which SKUs drive travel time, where bottlenecks emerge, and why lines stall. Start by measuring what matters most: touches per order, dwell time, and pick path distance, then turn insights into targeted, repeatable improvements.

02

A quick story: Tuesday’s forklift detour

A supervisor noticed frequent forklift U-turns near Aisle 12. Data confirmed a 19% detour rate tied to oversized pallets. After re-slotting high-cube SKUs, travel time dropped, congestion eased, and output rose by a full trailer’s worth per shift. Small observation, big analytical payoff.

03

Your role in the data journey

Analytics works when every role participates. Pickers tag exceptions, supervisors validate anomalies, engineers test hypotheses, and leaders champion adoption. Share your toughest choke point in the comments, and we’ll feature community-sourced experiments you can replicate in under two weeks.

Building the Data Backbone: WMS, IoT, and Clean Pipelines

Instrument the floor

Start with scan compliance and time-stamped events. Layer in IoT beacons on forklifts, smart scales at pack-out, and dock door sensors. These signals expose dwell hotspots, path inefficiencies, and cycle time variance, giving you a granular, trustworthy picture of warehouse reality.

Unify and cleanse

Integrate WMS, ERP, and labor systems into a single source of truth. Deduplicate SKUs, standardize units, and reconcile timestamps. Clean data shrinks the gap between report and reality, making every dashboard a reliable guide rather than a pretty but misleading picture.

Governance that scales

Define owners for metrics, access rules for teams, and retention windows for history. A lightweight data dictionary clarifies definitions—like what constitutes a pick attempt or late dispatch—so meetings focus on action, not arguments. Ask for our checklist in the comments if you want a starter template.

Inventory Optimization with Predictive Demand

Daily forecasts at the SKU-location level capture weekday patterns, promotions, and seasonality. Look beyond averages to intervals and volatility. When demand spikes are predictable, you can pre-position stock, smooth receiving, and allocate labor where it will protect service at the lowest cost.

Inventory Optimization with Predictive Demand

Right-size safety stock with probabilistic methods that consider demand variability and lead-time uncertainty. Stop hoarding; start modeling. One site cut excess by 14% while improving fill rate because buffers were placed at genuinely risky nodes, not just wherever anxiety happened to live.

Smarter Slotting and Layout Analytics

Heatmaps that reduce footsteps

Visualize picks per hour by location to find hidden detours and cold zones. Place high-frequency SKUs near dispatch points, eye level, and wider intersections. One re-slotting pass cut average picker travel by 22%, simply by aligning physical layout with data-informed flow patterns.

Re-slotting sprints, not marathons

Batch re-slot candidates weekly using threshold rules—velocity changes, affinity pairs, or seasonal flips. Keep moves small and measurable. Track a before-and-after metric set: travel distance, pick rate, and short stops. Comment to get our sprint template for incremental, low-disruption layout wins.

Labor Planning and Workforce Insights

01

Pair engineered labor standards with actual path, dwell, and exception data. You’ll spot where standards undercount congestion or overestimate line speed. Calibrated expectations convert tension into trust, helping teams focus on removing obstacles instead of disputing the scoreboard.

02

Forecast workload by hour and skill, then auto-generate shift mixes that minimize overtime while honoring preferences. Cross-train where variability demands it. Announce changes with visual dashboards so teams understand the why, not just the when, and volunteer for targeted upskilling opportunities.

03

Analytics reveals error patterns by station and time. Use short, focused refreshers triggered by thresholds—mis-scan streaks, quality flags, or new SKU layouts. Celebrate improvements publicly; nothing builds momentum like a visible, data-backed performance turnaround earned by the frontline.

Orchestrating Inbound, Outbound, and Yard with Data

Blend carrier ETAs, historical unloading time, and staffing forecasts to assign viable appointment slots. Overbooking drives chaos; underbooking wastes capacity. A balanced, data-driven schedule trimmed average dwell by eleven minutes per trailer and stabilized downstream picking workloads.

Continuous Improvement: KPIs, A/B Tests, and Storytelling

KPIs that align with the floor

Choose a compact set: on-time shipment rate, pick accuracy, units per labor hour, travel per pick, and dock-to-stock time. Tie targets to customer promises. When metrics reflect daily reality, teams engage because success feels achievable and visibly tied to their craft.

Run A/B in an operational environment

Pilot changes in matched zones and compare lift with pre-agreed acceptance criteria. Use short cycles and clear guardrails. Even a two-point improvement in pick accuracy can unlock compounding benefits downstream—fewer returns, faster packing, and happier customers who reorder sooner.

Tell the story, win the change

Translate numbers into narratives: fewer wasted steps means earlier lunches and safer aisles; faster dock turns mean calmer afternoons. Share dashboards at shift huddles, invite feedback, and publish weekly wins. Subscribe for templates that make your next improvement story impossible to ignore.